Our services

Here you will find all the services that Checkpoint Cornizzolo can offer you to improve your safety and comfort in flight.

Inspection

Inspecting a paraglider wing is a multi-step process.

The first step is to register the customer and enter the glider's identification data into our software.

We begin the inspection with the fabric porosity test. With the JDC/Hello tool, the porosity resistance time in seconds is recorded. This check is carried out at various points on the upper surface and lower surface of the leading edge. The data is reported on the intervention sheet.

The second check is the test of the fabric's tensile strength. Using a Bettsometer, a needle-like instrument that is stuck into the fabric to stretch it. The fabric passes the test if it can withstand a traction of 6 Newtons without damage.

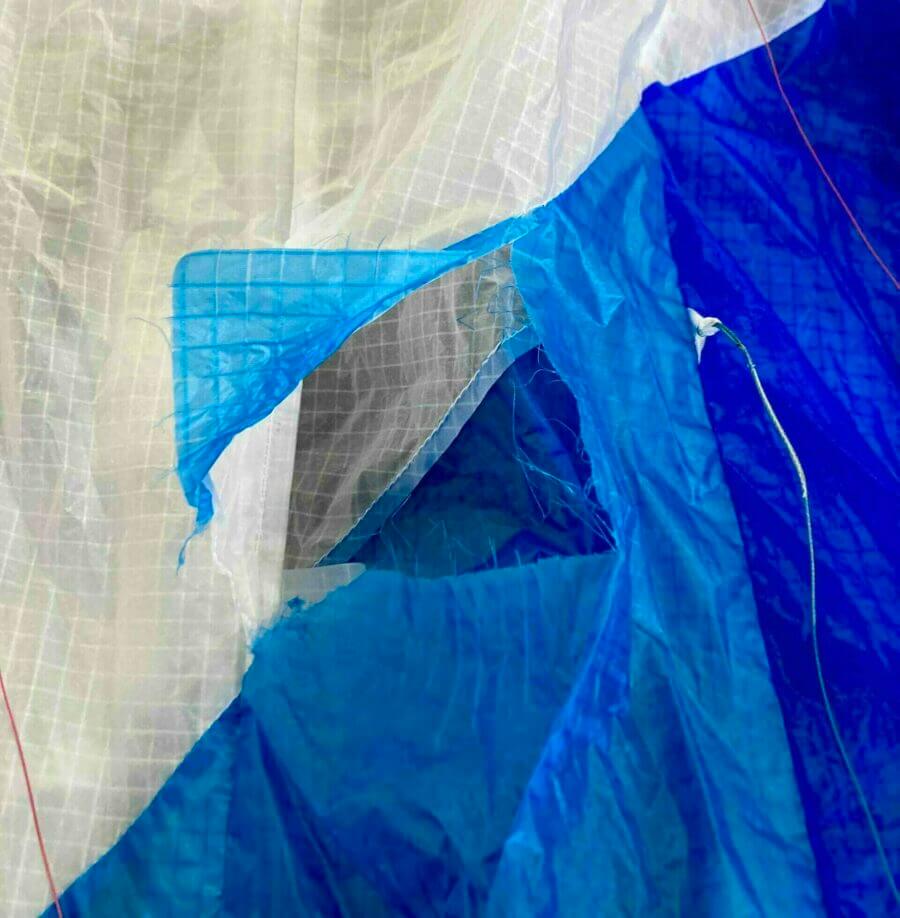

The visual inspection is then carried out. In this phase, the entire sail is carefully inspected, checking the fabric, attachment points, seams, ribs, lines and risers. The wing is suspended by the trailing edge in order to be emptied of dirt through the cell openings. The results of the inspection are noted in the intervention sheet.

Using a laser measuring device, the length of all the lines is checked. The recorded measurements are compared with the manufacturer's technical data. The differences are immediately highlighted in the application and the data is analyzed in order to make precise alignment corrections.

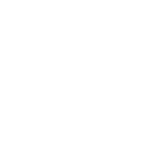

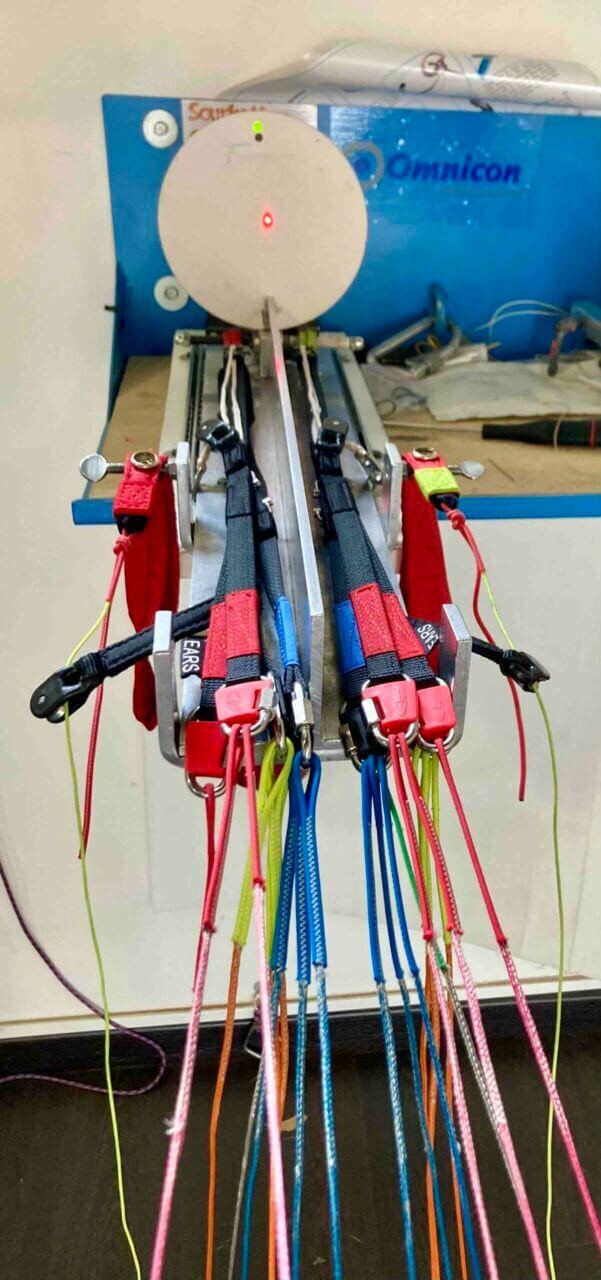

Si procede in fine alla verifica del carico di rottura delle linee principali e delle diramazioni con l’ausilio di un dinamometro con pistone oleodinamico. Le linee selezionate vengono trazionate fino alla rottura e il test risulta superato se esse si rompono oltre il valore minimo previsto. Il nostro software registra dieci volte al secondo i dati di carico subiti dal cordino e li memorizza nella scheda del controllo. Quest’ultimo test non sempre è necessario; viene eseguito in base al tipo di linee montate e alla valutazione dell’usura del parapendio.

Rescue parachute repack

Folding the emergency parachute is an operation that is recommended to be carried out annually.

Rescue parachute manufacturers require a specific folding method to be applied on each model.

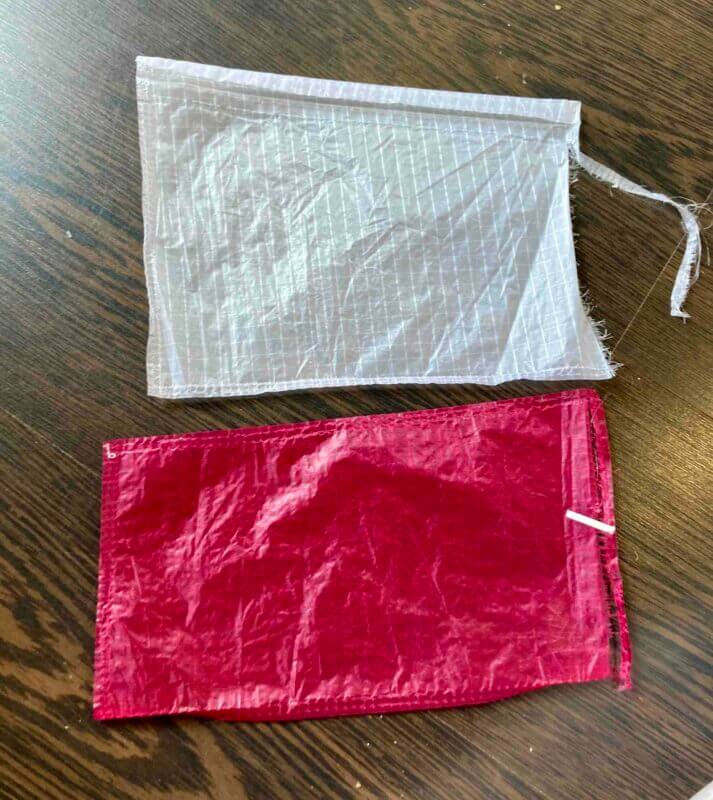

Once we have received the parachute, we remove it from its case (POD), unfold it and hang it for 72 hours so that it releases any humidity absorbed over time.

Once the drying period has passed, we proceed with folding according to the manufacturer's instructions.

Having reached the final stage, the elastics that hold the parachute lines in place are replaced and, if necessary, the elastic rings that close the POD with the pins are also replaced. Finally, the parachute is closed in its case and installed in the harness.

Repairs

Repairing a paragliding wing is a complex job that requires experience and skilled labor.

After registering the personal data we proceed with the inspection of the glider to determine the extent of the damage and quantify the cost of the repair to the customer. We then obtain the necessary materials. At Checkpoint we only use original materials that we order directly from the manufacturer. We proceed removing the damaged parts by unstitching them carefully. We cut the new fabrics to size and proceed with the reconstruction.

We do our best to make the repair almost invisible.

Our repairs keep the safety and performance of the glider unchanged.

Maintenance service on harnesses

A functional harness in perfect condition will make your flight safer and more comfortable.

Possiamo effettuare riparazioni e modifiche delle sellette da parapendio, sempre mantenendo inalterato il cinghiaggio portante, affinché sia mantenuta l’omologazione della casa costruttrice.

Viene eseguito un controllo visivo per determinare l’entità del danno o della modifica da apportare per poi quantificarne il costo al cliente. Vengono controllati tutti i componenti della selletta quali: cinghie, tessuto e punti di aggancio; verificata la funzionalità delle parti mobili come moschettoni e fibbie; la simmetria delle parti portanti e delle regolazioni.

Finally, the functionality of the rescue parachute release and extraction system will be checked.

Line replecement

When a sail is in good condition, but the lines have suffered excessive wear for various reasons, it is necessary to replace it.

Once the new lines have been received from the manufacturer, we proceed with taking the old lines apart and then assembling the new ones starting from the upper lines.

When all the lines have been assembled, the risers are assembled too and finally we check the trim of the wing.

Pick up service

With Checkpoint Cornizzolo you can request home pick up service of your sail.

Send us an email with the request and prepare the package attaching the order form. It is important that all your data is present and that someone is always present at the indicated address on the agreed day for collection.

The shipping cost of both collection and return service for the package is €35.00 (the cost may vary depending on the location and the size/weight of the package).